MARITIME MAINTENANCE SERVICES

Delivering Precision and Reliability for 120 years

Do you have a vessel that needs our help?

World Class Facilities

FFE’s DNV-approved workshop at the Australian Marine Complex in Henderson, Western Australia, is a highly versatile facility, purpose-built to undertake any kind of repair, maintenance, testing or fabrication task. The workshop provides easy access for mobile cranes and large trucks, as well as being equipped with an integrated 10 tonne gantry crane. And our NATA Accreditation gives us certification expertise for testing and calibration functions within the scope of our accreditation.

We are experts in propulsion systems with proven Defence experience, and have specialist, trained technicians for most marine diesel engines and cooling systems.

Our small, highly skilled team offers short turn-around on emergency dockings, and complete project management on repairs, rebuilds, installations, and testing, providing delivery on time, and minimising sailing delays

Experts in Propulsion Systems

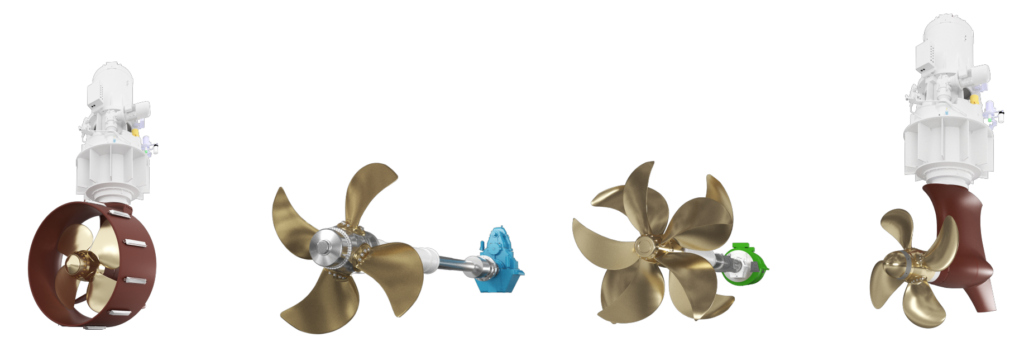

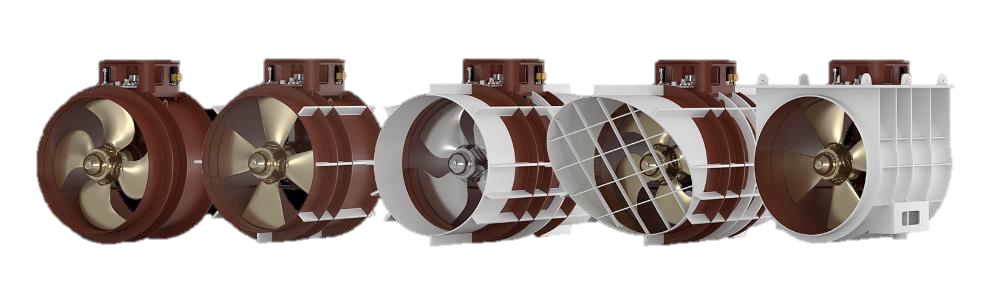

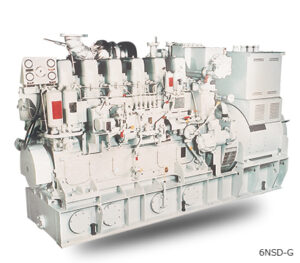

Our propulsion activities encompass servicing, repairing, refurbishing and replacing propulsion and positioning systems, and are underpinned by our exclusive partnership with Brunvoll Propulsion and Thruster Systems in Australian and New Zealand; and with JMAC for servicing Niigata Main Diesel Engines, and Propulsion, Thruster and Power Generation Systems.

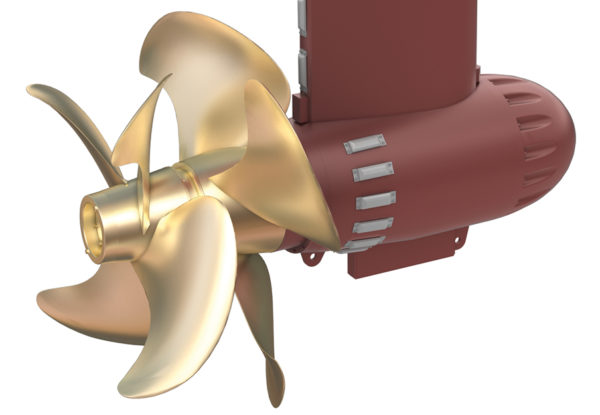

Brunvoll Propulsion Systems

Our Propulsion Competencies

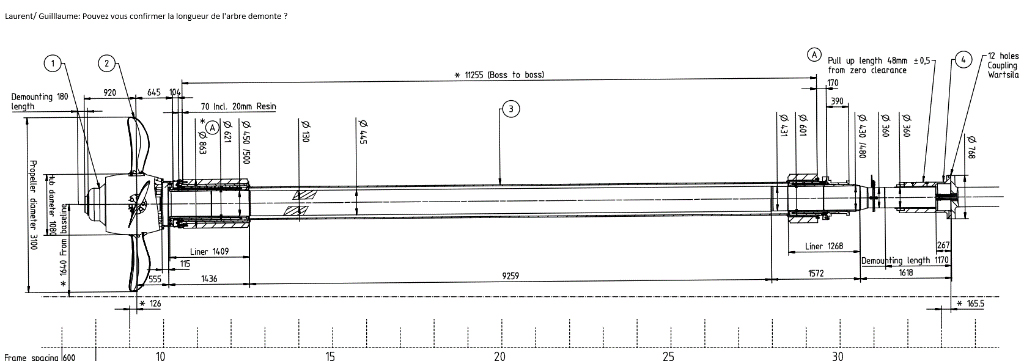

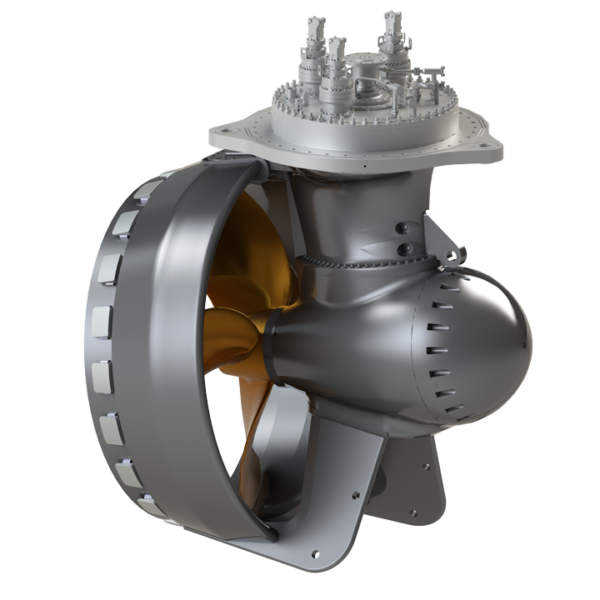

Our scope of works spans the full length of a vessel’s main propulsion system. Beginning with the engine, we service turbochargers, clutches, gear boxes, drive shafts, drive couplings, bearings, seals, propellers, and rudders. We also specialise in fitting and servicing tunnel or azimuth thruster manoeuvring systems with fixed or controllable pitch propellers.

Brunvoll Tunnel Thruster

Kongsberg Azimuth Thruster

Schottel SRP Rudder Propellor

Our Propulsion Capabilities

Our propulsion capabilities mean we are able to undertake major engine, gear box and slewing gear;

- Services

- Overhauls

- Reconditioning

- Replacement

As well as;

- Drive shaft and coupling inspection and rehabilitation

- Bearing re-metaling and machining

- Seal removal, refurbishment, and reinstallation

- Propeller and rudder repair and renovation

Through our Brunvoll and Niigata relationships we can supply parts and conduct scheduled, class services in accordance with the manufacturers’ recommendations.

Depending on the specific requirements of a project, we are able to provide our propulsion services on- vessel, in the shipyard or at our workshop.

Expertly Servicing a Wide Range of Gear

While subsystem support is an integral part of FFE’s broader propulsion services, the knowledge and experience of our in-house team of tradespeople and technicians is also available independently for preventative maintenance or breakdown repairs of engine room auxiliary equipment.

FIFI Pump Repairs and Refurbishment

FIFI Pump Installation

Our Subsystems Competencies

Our subsystems team deals with:

- Fuel systems including injectors, pumps, and tanks

- Cooling & heating systems including pumps, valves, pipework, boilers, heat exchangers and condensers

- Lubrication systems including pumps, filters & separators, and generators, compressors & turbochargers

We offer inspection, testing, diagnostic and reporting services; providing recommendations for repairs or remediation for any identified problems, and undertaking works on a ‘fixed-price’ or ‘do-and-charge’ basis.

Our Subsystems Capabilities

Tasks range from minor servicing of static and rotating machinery and equipment to full plant overhaul and change-out.

Our mechanical, fabrication and fitting capabilities include;

- Pulling down and rebuilding engines, compressors and generators

- Altering and re-manufacturing pipework

- Re-balancing shafts and rotors

- Retubing and reconnecting heat exchangers and condensers

- Repairing and refurbishing hard and resilient mounts and hangers

Our electrical and digital-control skills apply to instrumentation, controls, motors, and actuators. FFE also maintains and services replenishment at sea (RAS) and fuelling at sea (FAS) systems and rigs.

Rigging

While the core of our maritime rigging operations is based on our contracts with the Australian Department of Defence at both Garden Island (HMAS Stirling) and the Henderson Common Use Facility (CUF), our expertise is also available to merchant, commercial, and private vessels.

Our Rigging Competencies

FFE rigging services encompass a wide range of maritime elements, including flight deck nets for aircraft; lifting and restraint equipment for weapons handling; safety handrails, guards, and barriers; as well as bollards, load points, hooks, eye pads, slings, wire rope, synthetic webbing, chains and fittings for lifting, staying, tensioning, securing and materials handling.

Our Rigging Capabilities

Our services include supplying, fitting, repairing, refurbishing, replacing, testing and certifying rigging systems, equipment, and components; all strengthened by our NATA testing certification.

More than 100 years of Working with Metal

Our business began over 100 years ago as a foundry and general engineering company, and we still provide expert skills in working metal. We provide ongoing services to many long-standing customers, as well as one-off made-to-order projects

Our Welding and Fabrication Competencies

FFE work in steel, stainless steel, copper-nickel and aluminium. Our maritime fabrication focuses on repairs and modifications to ship hulls, cranes, ladders, and other ship-based or wharf-based elements. We also fabricate and repair equipment for the oil and gas, mining, hospital, transport and manufacturing sectors.

Our Welding and Fabrication Capabilities

Beyond our maritime activities, our team of coded welders / boilermakers is able to take on any light to medium fabrication project, including manufacturing, refurbishing or repairing boilers, economisers, pressure vessels, heat exchangers and condensers.

Specialists in Proof Load Testing

FFE is NATA Accredited for Proof Load testing of load-bearing structures and rigging setups, under ISO 17025 – General Requirements for the Competence of Testing.

Our NATA accreditation allows us to conduct Proof Load testing of equipment such as rigging and tensioning systems, guard rails, anchors, ladders, platforms, and lifting devices (including jacks) under load forces between 2.5kN to 500kN, depending on the product / equipment, to confirm the items conform to the relevant standard requirement.

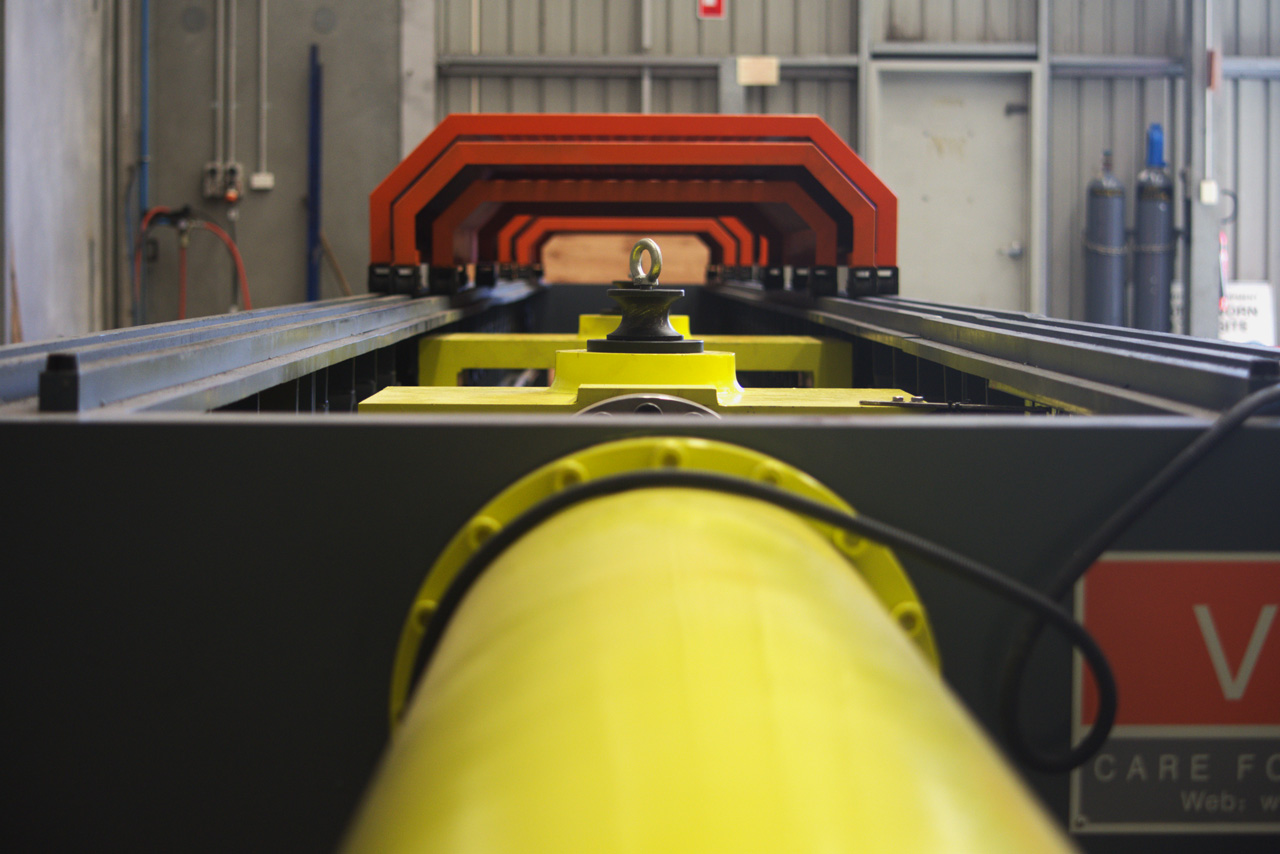

FFE is also able to perform NATA certified testing using our state of the art 1000kN Computerised Electro-hydraulic Servo Horizontal Tensile Test Bench installed at our NATA certified testing facility in Henderson. The Test Bench capabilities include proof load testing, break load testing, and low cyclic testing of steel wire ropes, chains, spreader beams, webbing slings, shackles, etc. The testing space has a maximum tensile testing length of 12m, and a load measuring range of 2%- 100%, with a test force accuracy better than ±1%.

In addition to Proof Load testing, our SoA also covers pressure testing of Pipelines, Pressure Fittings, and Valves, as well as the only NATA Certified testing of winch brake rendering in Western Australia.

Testing of mooring winch brake rendering supports vessel owners to comply with the Port of Fremantle’s mandate for winch brake rendering tests every 24 months and our expert technicians are fully equipped to conduct onboard testing, or where necessary for removal and testing at our NATA Certified Testing Facility within the AMC.

All our test rigs are calibrated to the requirements of our NATA Scope of Accreditation (SoA), and all testing that is conducted in accordance with our SoA is certified and traceable under NATA requirements and can be carried out onsite, or at our NATA accredited testing facility in Henderson WA.

Flight Deck Net Load Testing

Gangway Load Testing

Trusted Partners

FFE is a trusted partner of some of the world’s most respected global operators within the commercial and defence maritime industries. Our expertise in the maintenance of propulsion and positioning systems in sea vessels has positioned us as the sole agent in Australia and New Zealand for Brunvoll, as service agents for SCHOTTEL to support OEM-quality repairs for SCHOTTEL products in Western Australia, and the preferred partner of JMAC in servicing Niigata systems. FFE also partner with AU Defence prime contractors such as BAE and Babcock in providing maintenance services and repairs for Navy vessels, and are a member of the Henderson Alliance “Promoting Western Australian

SME Capability to the World”. If you are looking for a partner to support your work within the maritime maintenance industry get in touch and let us know how we can help. Here are just some of our partners …